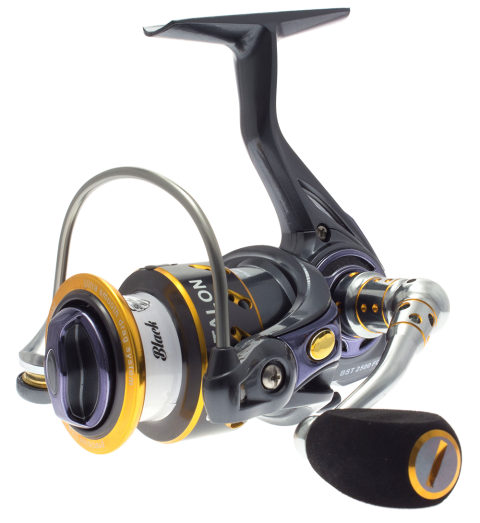

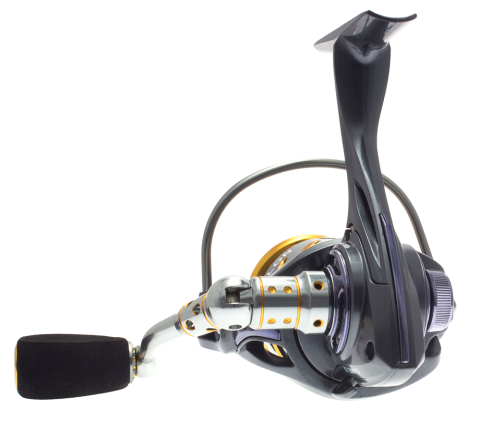

TALON

-

6+1 Ball Bering

6+1 Ball Bering

6 ball bearings, 1 roller bearing

-

High grade steel ball bearing

High grade steel ball bearing

High-quality precision bearings manufactured in Japan.

-

Infinite anti-reverse

Infinite anti-reverse

The new system of a stopper of a return course instantly blocks return movement of a rotor without the slightest rollback back, guaranteeing a timely reliable cut -

Cone bail

Cone bail

The conical base of the arch of the woodcutter, preventing overlapping of the line along the support of the roller. -

Air bail

Air bail

A light hollow shackle of a wood scraper made of high-quality stainless steel. Reduces the vibration of the coil and allows you to smoothly close the arch of the forest tiller without impact.

-

Computer balanced rotor

Computer balanced rotor

The newest system of computer balancing of the rotor, excluding the possibility of its beating during rotation and ensuring the soft operation of the mechanism.

-

Antitwist roller

Antitwist roller

The special design of the logging roller is specially designed to reduce twisting of the line when winding. When winding the coil, the fishing line is dumped into the technological groove of the roller and passes through one point, whereby the line does not have the ability to "hang" over the entire surface of the roller, which subsequently avoids the formation of loops during casting. -

Power gear

Power gear

Power transmission gear "steel on bronze", consisting of carbide specially treated steel gear and a sharp bronze screw screw, provides smooth operation of the mechanism and increased service life of the coil.

-

Cast lock

Cast lock

Locking system of the forester arch in open position, preventing spontaneous closing of the arch of the forest depositor during casting

Specification

- 6 ball bearings

- 1 roller bearing

- Instant anti-reverse system

- Hollow Bail Arm

- Cone Bail (prevents line twist)

- Antitwist Roller

- Computer balanced rotor

- Power gear

- Reel body and rotor are made of ultralight alloy

- Graphite spare spool

| Model |

Gear Ratio |

Bearings |

Weight, g. |

Line Capacity, |

| BST2000FD | 5,2:1 | 6 + 1 | 245 | 0,250/130; 0,230/155; 0,200/200 |

| BST2000FDS | 5,2:1 | 6 + 1 | 240 | 0,200/150; 0,250/100; 0,280/80 |

| BST2500FD | 5,2:1 | 6 + 1 | 255 | 0,250/160;0,230/190;0,200/250 |

| BST2500FDS | 5,2:1 | 6 + 1 | 250 | 0,200/150;0,250/100;0,280/80 |

| BST3000FD | 5,2:1 | 6 + 1 | 280 | 0,350/130;0,300/175;0,250/250 |

| BST4000FD | 5,2:1 | 6 + 1 | 310 | 0,300/200; 0,350/140; 0,400/100 |